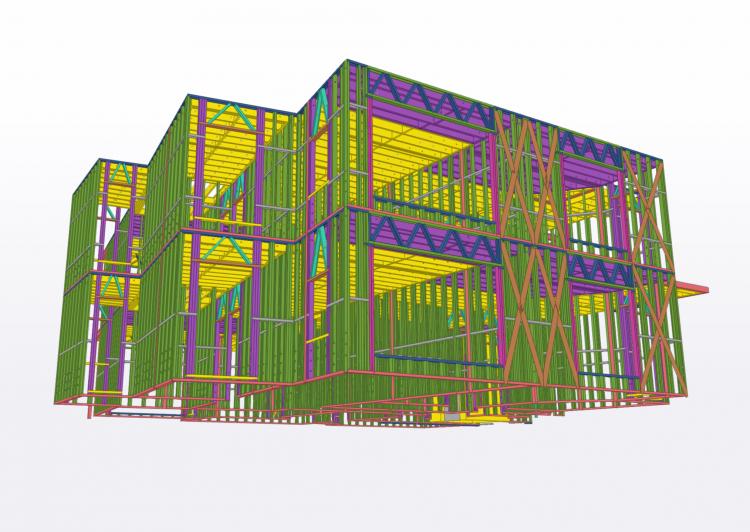

When it comes to offsite construction, accuracy is key if we as an industry are to achieve the speed and carbon savings promised by the modern method. Automation and digitisation have a big role to play in achieving this, helping to save time, streamline the repetitive and reduce the likelihood of human error – as Frameclad, the light-gauge steel frame manufacturer, knows…

A key part of this digital approach is the integration between 3D modelling software and fabrication machinery, connecting the detailing and manufacturing stages. The partnership between Howick and Tekla software is a great example of this, with a number of plug-in tools available to aid the construction of models using Howick machinery.

Speaking about their use of the Howick tools extension in Tekla Structures, Jack Murphy, Senior Design at Frameclad, said: "We use the tools for all panelised systems, particularly the Howick Connection Tool. For example, when detailing C-Sections, we can simply load in the 'lip cut' and apply to all highlighted intersections, with the software automatically removing the lip from the steel. This will then allow the adjacent swaged stud to slide down into the base section when preassembled in the factory, prepared for site installation.

"Similarly, with just a couple of clicks we can detail 'dimples', creating an indent at the components' intersections, which – when fitted together in the factory - acts as a fixing guide and allows for the fixing to fit flush against the frame.

"As a business, we have our own pre-sets in the Howick Connection Tool. That's one great thing about the tool: you can either load in pre-sets bespoke to your company's manufacturing processes, such as using a specific tool or punch size; or you can customise it, creating more bespoke detailing to suit scheme requirements and provide further scope. You can then easily apply all set connections and cuts with just a couple of clicks.

"This idea of a 'click and go' approach is hugely valuable; it significantly helps the company run more efficiently in its operations. The time savings are considerable, with the ability to essentially 'copy and paste' connections. This is particularly ideal for offsite construction where similar connection details are quite frequent – we only really have a small selection of connections that we use day-to-day. This has enabled us to adopt a more streamlined approach, drastically cutting down on our design time.

"The accuracy levels are another big benefit - what you see in the model is what will get fabricated and delivered to site."

In addition to the Howick Connection Tool, Frameclad utilises the Howick Export Tool, also available in Tekla Structures. Jack explained: "Once we have the completed and approved design, frame numbers are generated, with every part given a reference. A bill of materials on associated assembly drawings are all automatically created by Tekla, in much the same way as an IKEA flat pack – just on a larger scale.

"Using the Export Tool, we can export the Tekla model as a CSV file, which is then plugged directly into the Howick cold roll forming machinery we have in our factory. The accuracy attained here is tremendous and is the core benefit of this integrated link. While it is possible to transfer the model data manually, it's a time-consuming process. Instead, we can essentially leave the machinery to it and rely on the cold roll-formed steel being accurate, removing the chance of human error."

The part references are then printed on each component once processed through the Howick machine, to assist with assembling the frames when read in conjunction with the assembly drawings. The references also indicate where each panel will be located on site.

The Chocolate Factory development in London's Wood Green is a great example of this automated and integrated approach, with the smart link between Tekla software and the cold roll forming machinery allowing for efficient manufacturing of the structure's wall frames and roof cassettes.

To learn more about Tekla Structures, please visit: www.tekla.com/uk

Stay in touch: